UPCOMING EVENTS

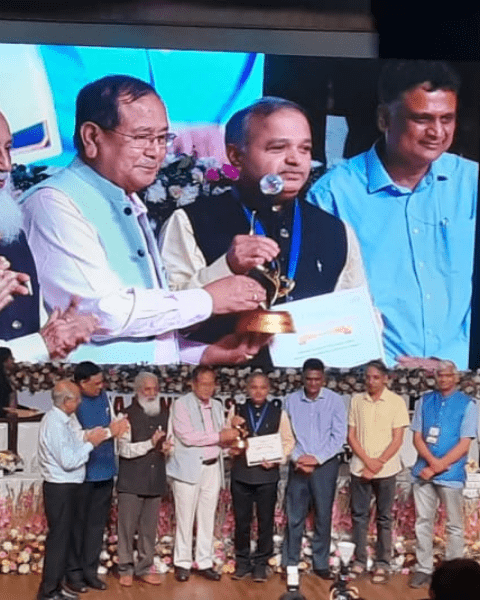

NIRF 2023 - All India Ranks

Architecture and Planning : 2nd

View Certificate View DetailsInnovation - 8th

View Certificate View DetailsEngineering : 23rd

View Certificate View DetailsOverall : 54th

View Certificate View DetailsManagement - 75th

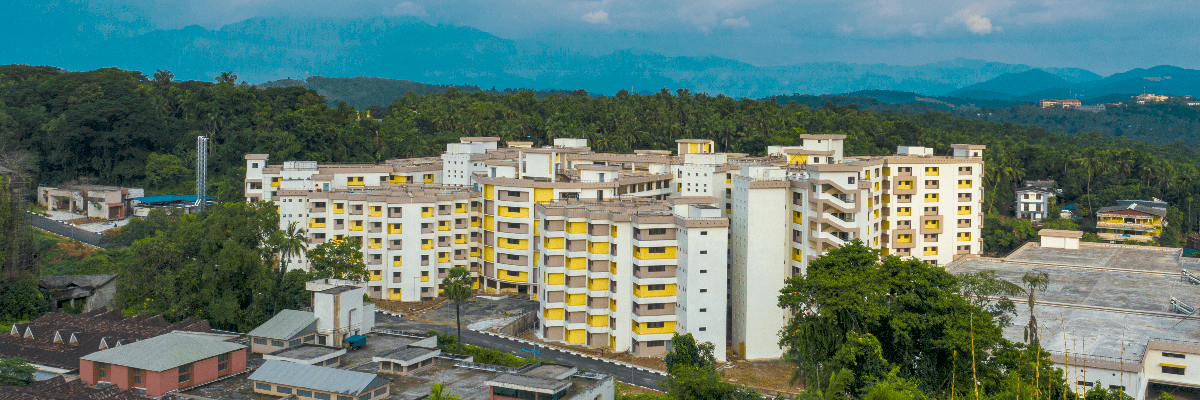

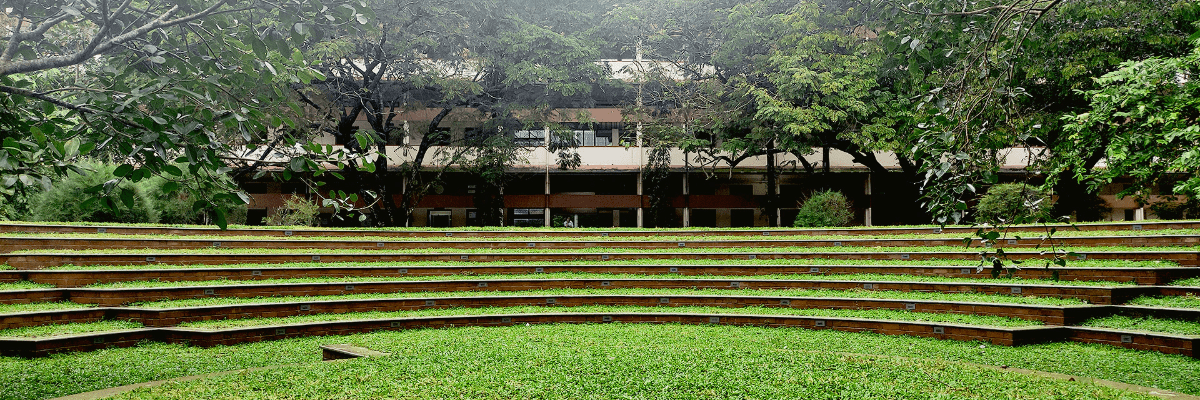

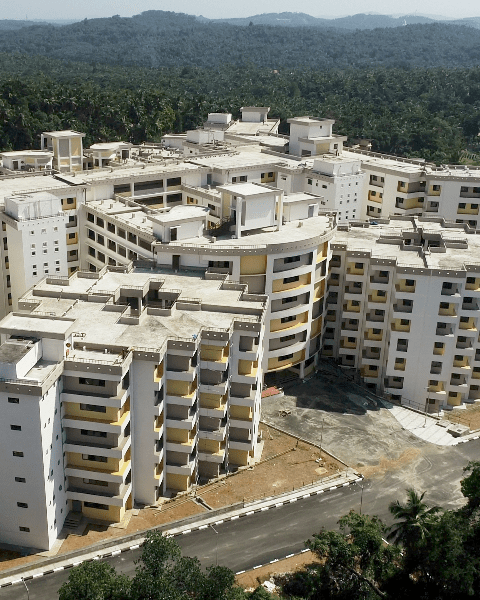

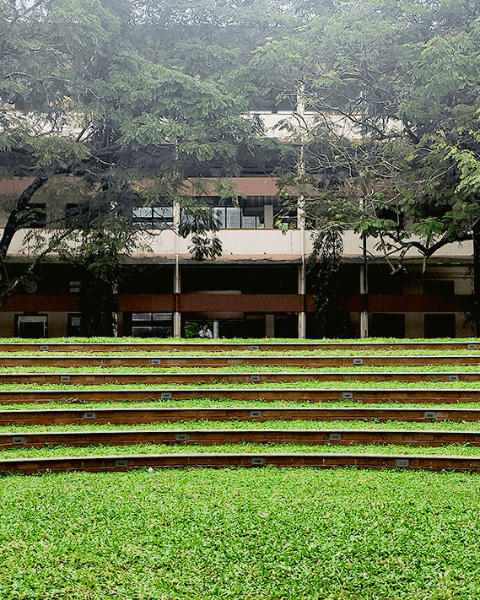

View Certificate View Details285 Acres

CAMPUS AREA

334852 Sq.m

BUILT-UP SPACE

40000

ALUMNI

43

PATENTS

155 (Last 5 Years)

RESEARCH PROJECTS

4000+ (Last 5 Years)

PUBLICATIONS

90.9%

PLACEMENTS

49

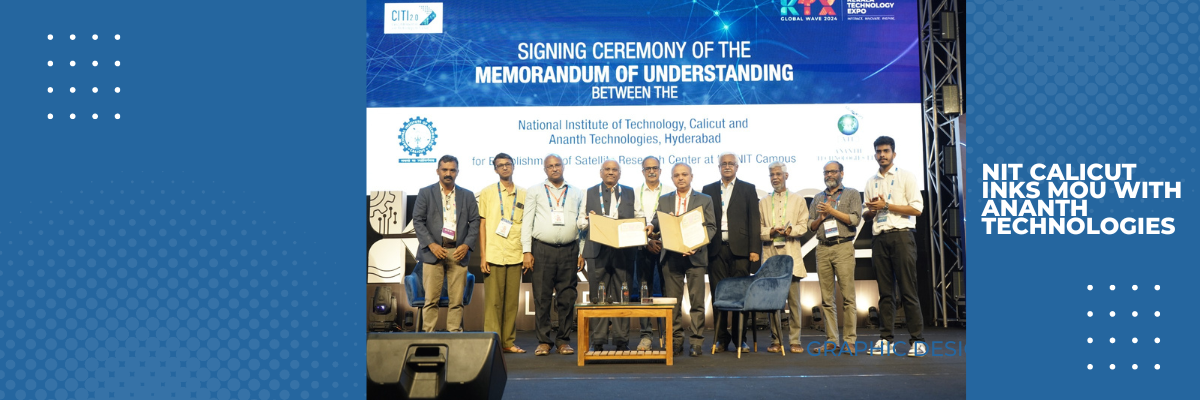

MOUs

RANKING

NIRF 2023 - All India Ranks

Architecture and Planning : 2nd

View Certificate View DetailsInnovation - 8th

View Certificate View DetailsEngineering : 23rd

View Certificate View DetailsOverall : 54th

View Certificate View DetailsManagement - 75th

View Certificate View DetailsSTATISTICS

285 Acres

CAMPUS AREA

334852 Sq.m

BUILT-UP SPACE

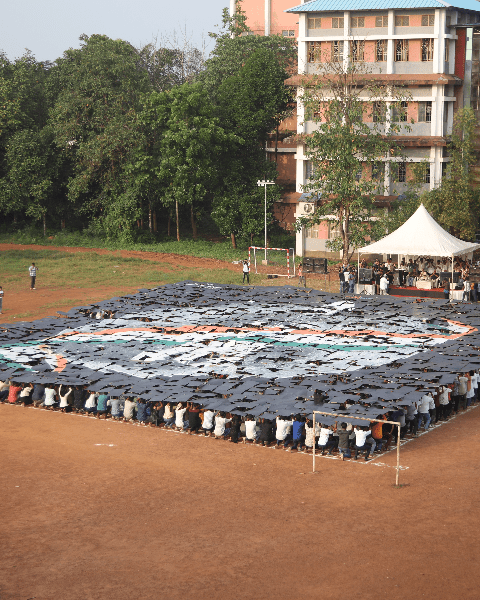

40000

ALUMNI

43

PATENTS

155 (Last 5 Years)

RESEARCH PROJECTS

4000+ (Last 5 Years)

PUBLICATIONS

90.9%

PLACEMENTS

49

MOUs